- Who we are

- Governance

- Products

- PACKAGING TECHNOLOGY OPEN TO EVERYONE

- L-seal hood packersSL Series

- L-seal hood packersS Series

- L-sealer, automatic L-sealer, shrinking tunnelFP Series

- Continuous automatic sealers with shrink tunnelHS Series

- Automatic flow pack machinesFW Series

- Semi-automatic and automatic shrink wrappers with sealing barBP Series

- Automatic overlap shrink wrappersXP Series

- Wrap-around case packersWPS Series

- Automatic handle applicatorsHA Series

- Services

- Media center

- News

- Contacts

- Careers

- Who we are

- Governance

- Products

- PACKAGING TECHNOLOGY OPEN TO EVERYONE

- L-seal hood packersSL Series

- L-seal hood packersS Series

- L-sealer, automatic L-sealer, shrinking tunnelFP Series

- Continuous automatic sealers with shrink tunnelHS Series

- Automatic flow pack machinesFW Series

- Semi-automatic and automatic shrink wrappers with sealing barBP Series

- Automatic overlap shrink wrappersXP Series

- Wrap-around case packersWPS Series

- Automatic handle applicatorsHA Series

- PACKAGING TECHNOLOGY OPEN TO EVERYONE

- Services

- Media center

- News

- Contacts

- Careers

Automatic flow pack machines

FW Series

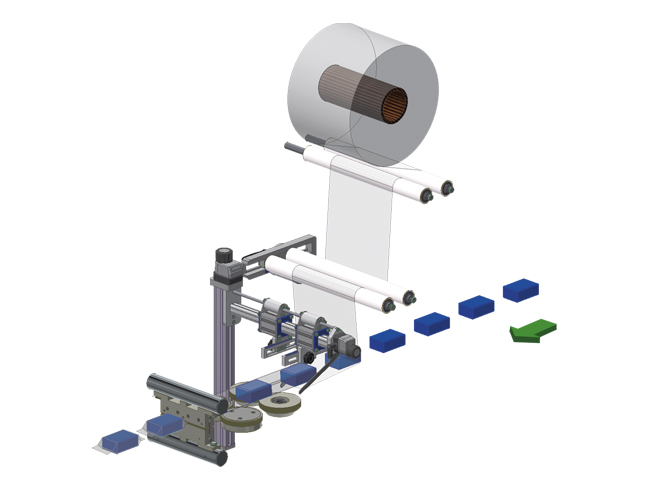

FW300E - Flow pack machine with rotary sealing and upper film reel

The new FW series of automatic packaging machines with flow pack system, designed according to Industry 4.0 and IoT (Internet of Things) technological platforms, is the family of machines that completes the SMIPACK range. The version with rotary bar sealing system is composed of 7 models (five with upper reel, three of them dedicated to the entry-level sector, and two with lower reel) and packs a wide range of products with irregular shapes and small dimensions that arrive at the machine either loose (single doses) or previously grouped (multipack); the products are placed in packages made up of simple or coupled flexible material with a maximum output of 200 products/minute (based on the selected model). The film sealing & folding systems, combined with the dynamic and adjustable conformer, make process regulation on the FW models versatile and fast.

| Power supply | 220 - 240 V |

| 1PH+N+PE | |

| 50/60 Hz | |

| Installed power | 2650 W |

| Compressed air pressure | - bar |

| Sealing bar | 150 mm |

| Maximum product height | 60 mm |

| Speed up to | 80 ppm* |

| Maximum size of film reel | 300 - ø 300 mm |

| Machine size | 2645 x 795 mm |

| h 1590 - 1690 mm | |

| Machine net weight | 330 kg |

(*) Products per minute. The stated speed can change according to the product size, the pack collation and the type of film used.

- High reel flow pack machine

- Sealing system with rotary bar

- Sliding surfaces of the products in AISI304

- Infeed with adjustable guides and easily removable interlocking vanes

- Longitudinal sealing consisting of 2 pairs of drive wheels, the first pair pulls the film and the second does the sealing

- Manual opening of the longitudinal sealing wheels

- High reel holder with mechanical clutch

- Manual closing reel holder shaft

- Standard dynamic film conformer with position indicator with numerical display

- Cross sealing with bar 150 mm - 5.91” width

- Variation of the sealing bar height position by handwheel

- Motorized product outfeed conveyor adjustable in height by handwheel

- Drawers to collect product waste, under the entire length of the infeed conveyor

- Printed film centering device, no product - no bag, and end of film reel sensor included

- Motors configuration controlled by inverters: infeed conveyor/longitudinal sealer/ outfeed conveyor with independent asynchronous motors

- Motors configuration controlled by drivers: cross sealer with brushless motor

- Machine stop in phase

- FLXMOD® control system equipped with:

- operator Interface with Panel PC and 7” full-colour touch screen display with PLC user-friendly

- IN/OUT control modules for digital, analog inputs/outputs and thermocouple-reading control.

- This system is able to check all operations, simply and precisely, such as:

- two sealing temperature adjustments: one on the longitudinal sealer and one on the cross sealer

- electronically controlled conveyor belt speed

- process statistics:

- pack counter

- instantaneous production

- machine efficiency

- Possibility of scheduling up to 50 different work cycles

- Emergency button

- Reduced power consumption

- Compliance with CE regulations

Contact us

- SMIPACK S.p.A.

- Address: Via Piazzalunga, 30

24015 San Giovanni Bianco BG

Italy - Phone: +39 0345 40.400

- E-mail: info.smipack@smigroup.net

- Monday - Friday: 08:00 - 12:00 / 13:30 - 17:30

Saturday - Sunday: Closed

Privacy statement

TRANSPARENCY

![]()

Lawfulness of processing

All activities relating to personal data processing shall be lawful (consent, contract obligations, vital interests of the data subject or of third parties, compliance with legal obligations to which the controller is subject, public interest or exercise of official authority, legitimate interest pursued by the controller or by third parties).

![]()

Information statement

The information statement has been improved and updated to the new regulations (art. 13 and 14 GDPR).

![]()

Rights of the data subjects (right of access, right to erasure-right to be forgotten, right to restriction of processing, right to object, right to data portability)

Technical and organization measures have been adopted to ensure the data subject's exercise of his rights and to meet the data subject requirements.

![]()

Controllers, processors

Based on the new principle of “accountability”, SMI Group organization was re-defined, in order to proactively ensure integral compliance with the Regulation.

Redefinition of the role of data processors and service suppliers whose activity implies personal data processing.

![]()

Risk of data processing; accountability measures taken by controllers and processors (Impact assessment, record of processing activities, security of processing, data breach)

The “Conformity document”, including records of data processing activity, plans, adopts and demonstrates all technical and organizational measures taken to adequately perform the data processing activities and specifies the necessary procedures to be adopted to notify data breach.

![]()

Transfer of personal data to international organizations

Smipack adheres to the general principles and guarantees concerning the transfer of personal data to third Countries.

The Controller is:

SMIPACK S.p.A.

Head office: Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) ITALY

VAT nr: IT02529010163 - R.E.A. 234981

For further information, write to: privacy@smigroup.net

According to the European Regulation 679/2016, the data subject is entitled to exercise the rights set forth in the Regulation.

The integral version of art. 15; 16; 17; 18; 20; 21; 77 of the European Regulation is attached to this document.

In order to exercise your rights, please send the application form duly filled in to the Controller's address.

Legal notice

SMIPACK S.p.A.

Società sottoposta a direzione e coordinamento da SMIGROUP S.p.A.

Società appartenente al GRUPPO IVA SMI INDUSTRIES

Sede amministrativa:

Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

Tel. +39 0345 40.400 - Fax: +39 0345 40.409 - www.smipack.it

C.F. 02529010163 - P. IVA IT04471940165 - R.E.A. 302062

Iscr.Reg.Imprese 02529010163 - Cap. Soc. € 1.000.000 i.v.

Sede legale:

Via Monte Grappa, 7 - 24121 Bergamo (BG) - ITALIA

Unità produttiva:

Via Piazzalunga, 30 - 24015 San Giovanni Bianco (BG) - ITALIA

Tel. +39 0345 40.400 - Fax: +39 0345 40.419

Ufficio vendite:

Via Piazzalunga, 30 - 24015 San Giovanni Bianco (BG) - ITALIA

Tel. +39 0345 40.400 - Fax: +39 0345.40.409