- Who we are

- Governance

- Products

- PACKAGING TECHNOLOGY OPEN TO EVERYONE

- L-seal hood packersSL Series

- L-seal hood packersS Series

- L-sealer, automatic L-sealer, shrinking tunnelFP Series

- Continuous automatic sealers with shrink tunnelHS Series

- Automatic flow pack machinesFW Series

- Semi-automatic and automatic shrink wrappers with sealing barBP Series

- Automatic overlap shrink wrappersXP Series

- Wrap-around case packersWPS Series

- Automatic handle applicatorsHA Series

- Services

- Media center

- News

- Contacts

- Careers

- Who we are

- Governance

- Products

- PACKAGING TECHNOLOGY OPEN TO EVERYONE

- L-seal hood packersSL Series

- L-seal hood packersS Series

- L-sealer, automatic L-sealer, shrinking tunnelFP Series

- Continuous automatic sealers with shrink tunnelHS Series

- Automatic flow pack machinesFW Series

- Semi-automatic and automatic shrink wrappers with sealing barBP Series

- Automatic overlap shrink wrappersXP Series

- Wrap-around case packersWPS Series

- Automatic handle applicatorsHA Series

- PACKAGING TECHNOLOGY OPEN TO EVERYONE

- Services

- Media center

- News

- Contacts

- Careers

WPS 600R-K, Smart boxes for cans and glass bottles in the beverage sector

| |||

| The beverage sector is one of the most important in the B2C market and, especially for the marketing of products intended for the single-use segment, favors the use of metal cans | |||

| These containers require sturdy and resistant packaging, able to protect the content from shocks and damages during the transport and distribution phases. Starting from these premises, SMIPACK has decided to expand its WPS range of automatic case packers with wrap-around system by launching the new WPS 600R-K model; the latter has the same technical features, technological quality and operational flexibility as other models in this range, with the further advantage of using pre-glued cardboard instead of traditional flat cardboard, for packaging in wrap-around boxes. | |||

Cardboard boxes: | |||

| Very often soft drinks, beer and energy drinks are bottled in metal and glass containers, since these materials feature ductility, malleability, barrier effect and preservation of the content properties, in compliance with manufacturers' needs. However, the cylindrical containers (cans or bottles) used must in turn be protected against the damage they may suffer during transport from the production plant to the point of sale, especially in those countries where the road network is not in good condition. | ||

| For this purpose, cardboard boxes are the ideal choice for packing glass bottles and metal cans, as they have exceptional strength and robustness properties that are very useful throughout the distribution chain. In addition, they are made of 100% recyclable material, thus enabling the beverage industry to reduce its carbon footprint, and can be used as a promotional vehicle, as their external surface can be customized with highly visible advertising graphics. |  | ||

Two technical innovations | |||

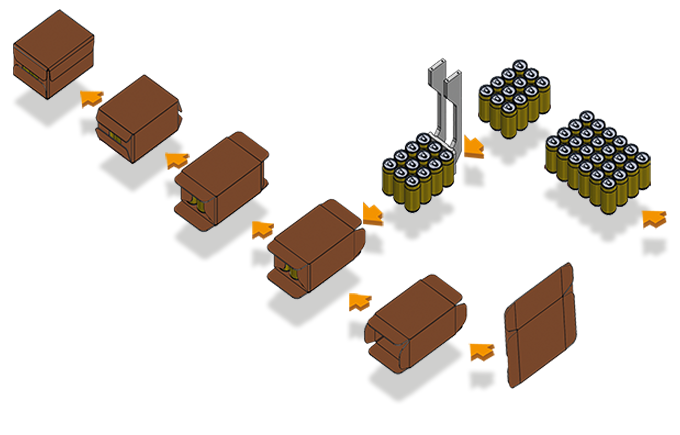

| The main innovations of the WPS 600R-K model compared to the rest of the range are represented by the newly-developed carton magazine, which contains pre-glued and already folded cartons instead of open cartons, and by the system used for forming the boxes. | |||

| |||

| The machine picks up one cardboard at a time by means of a suction cup device that, while moving from the warehouse to the work table, performs a misaligned movement to open the carton before placing it on the work table, where two side flaps hold it in place as it moves towards the loading area. | Subsequently, by means of a motorized push-in device with two axes, the loose product is moved laterally inside the carton to create the pack format selected by the control panel of the case packer. Finally, another device folds and glues the side flaps of the cardboard to make the finished box. | ||

| Thanks to the innovations introduced and the use of pre-glued carton, the entire packaging process takes place more efficiently and quickly than the one of traditional packaging solutions with a wrap-around system. | |||

To better understand how this new pre-glued cardboard | |||

| |||

|

| |||

| For further information on the new WPS 600R-K case packer and on all other packaging solutions supplied by SMIPACK, we invite you to contact our sales department. | |||

Contact us

- SMIPACK S.p.A.

- Address: Via Piazzalunga, 30

24015 San Giovanni Bianco BG

Italy - Phone: +39 0345 40.400

- E-mail: info.smipack@smigroup.net

- Monday - Friday: 08:00 - 12:00 / 13:30 - 17:30

Saturday - Sunday: Closed

Privacy statement

TRANSPARENCY

![]()

Lawfulness of processing

All activities relating to personal data processing shall be lawful (consent, contract obligations, vital interests of the data subject or of third parties, compliance with legal obligations to which the controller is subject, public interest or exercise of official authority, legitimate interest pursued by the controller or by third parties).

![]()

Information statement

The information statement has been improved and updated to the new regulations (art. 13 and 14 GDPR).

![]()

Rights of the data subjects (right of access, right to erasure-right to be forgotten, right to restriction of processing, right to object, right to data portability)

Technical and organization measures have been adopted to ensure the data subject's exercise of his rights and to meet the data subject requirements.

![]()

Controllers, processors

Based on the new principle of “accountability”, SMI Group organization was re-defined, in order to proactively ensure integral compliance with the Regulation.

Redefinition of the role of data processors and service suppliers whose activity implies personal data processing.

![]()

Risk of data processing; accountability measures taken by controllers and processors (Impact assessment, record of processing activities, security of processing, data breach)

The “Conformity document”, including records of data processing activity, plans, adopts and demonstrates all technical and organizational measures taken to adequately perform the data processing activities and specifies the necessary procedures to be adopted to notify data breach.

![]()

Transfer of personal data to international organizations

Smipack adheres to the general principles and guarantees concerning the transfer of personal data to third Countries.

The Controller is:

SMIPACK S.p.A.

Head office: Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) ITALY

VAT nr: IT02529010163 - R.E.A. 234981

For further information, write to: privacy@smigroup.net

According to the European Regulation 679/2016, the data subject is entitled to exercise the rights set forth in the Regulation.

The integral version of art. 15; 16; 17; 18; 20; 21; 77 of the European Regulation is attached to this document.

In order to exercise your rights, please send the application form duly filled in to the Controller's address.

Legal notice

SMIPACK S.p.A.

IVA SMI INDUSTRIES Group

Headquarters: Via Carlo Ceresa, 10

24015 San Giovanni Bianco (BG) ITALY

Registered office: Via Monte Grappa, 7 - 24121 Bergamo (BG) - ITALY

VAT: 04471940165 - TAX code: 02529010163 - R.E.A.: 234981

Share capital: Euro 5.000.000 i.v.