- Who we are

- Governance

- Products

- PACKAGING TECHNOLOGY OPEN TO EVERYONE

- L-seal hood packersSL Series

- L-seal hood packersS Series

- L-sealer, automatic L-sealer, shrinking tunnelFP Series

- Continuous automatic sealers with shrink tunnelHS Series

- Automatic flow pack machinesFW Series

- Semi-automatic and automatic shrink wrappers with sealing barBP Series

- Automatic overlap shrink wrappersXP Series

- Wrap-around case packersWPS Series

- Automatic handle applicatorsHA Series

- Services

- Media center

- News

- Contacts

- Careers

- Who we are

- Governance

- Products

- PACKAGING TECHNOLOGY OPEN TO EVERYONE

- L-seal hood packersSL Series

- L-seal hood packersS Series

- L-sealer, automatic L-sealer, shrinking tunnelFP Series

- Continuous automatic sealers with shrink tunnelHS Series

- Automatic flow pack machinesFW Series

- Semi-automatic and automatic shrink wrappers with sealing barBP Series

- Automatic overlap shrink wrappersXP Series

- Wrap-around case packersWPS Series

- Automatic handle applicatorsHA Series

- PACKAGING TECHNOLOGY OPEN TO EVERYONE

- Services

- Media center

- News

- Contacts

- Careers

Automatic wrap-arownd case packers

WPS Series

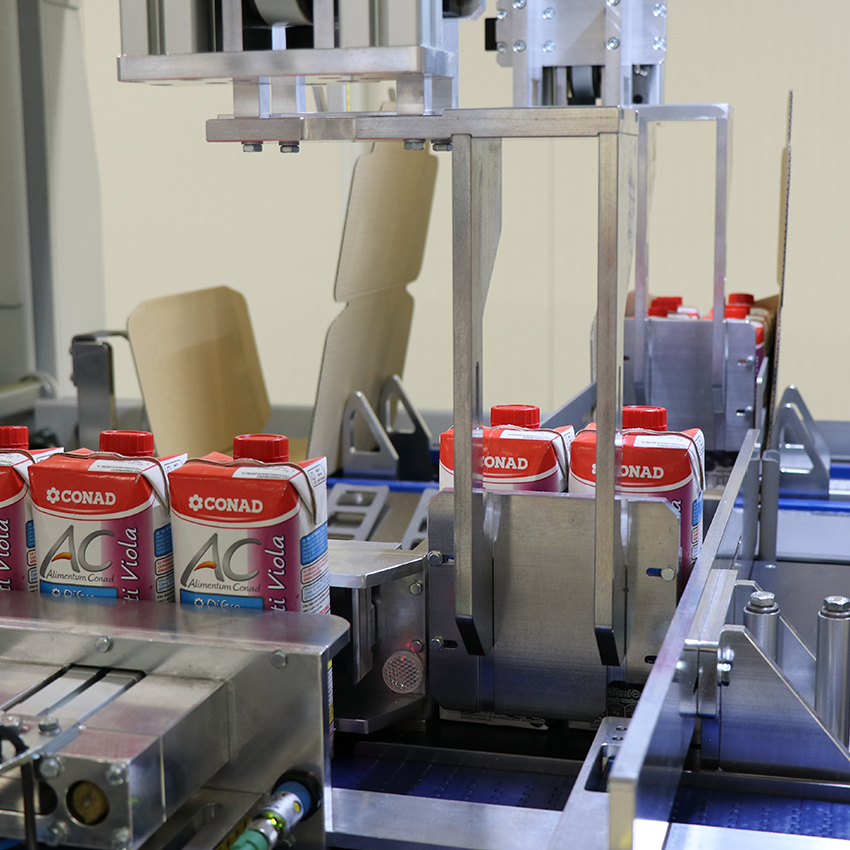

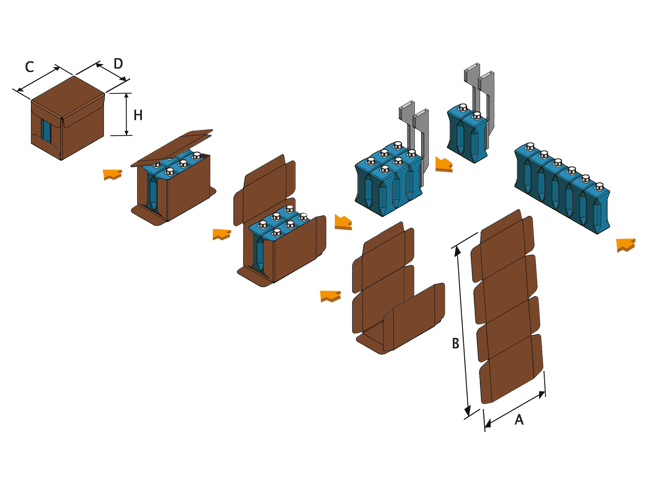

WPS 150R - Automatic wrap-around case packer with in-line infeed

The WPS series of automatic wrap-around case packer are suitable for packing a wide range of products in tray, open case, closed case, shelf-ready or display and for meeting the highest production standards and quality regulations.

Its compact design reduces the need for large spaces for installation and the extensive use of high-tech components enables to reach high productions in a short time. The WPS case packers allow to work three different types of cardboard: micro corrugated, corrugated and kraft, and can reach productions up to 25 packs/minute.

MARKET SECTORS

Beverage industry (milk, water, soft drinks, beer, wine, etc.), preserved foods (tomatoes, pickle, sauces, etc.), edible oil, aerosols, cosmetics, pharmaceutical, shampoo-detergents, oil lubricants, logistic, co-packers.

| Power supply | 220 - 240 / 380 - 415 V |

| 3PH + PE / 3PH + N + PE | |

| 50/60 Hz | |

| Installed power | 9700 W |

| Air pressure | 6 Bar |

| Required air | 17 Nl/p* |

| Speed up to | 20 p/min.** |

| Product minimum height | 75 mm |

| Product maximum height | 350 mm |

| Working board height | 960 - 1105 mm |

| Machine size | 4790 x 2415 mm |

| h 2190-2335 mm | |

| Machine net weight | 1935 Kg |

(*) Normal Iiters per pack.

(**) Packs per minute. The stated speed can change according to the product size, the pack collation and the type of material used.

- Automatic wrap-around case packer with in line infeed

- Sliding protection doors with deceleration device.

- Blank magazine at fixed height, equipped with motorized conveyor

- Photocell for stock of cardboards

- Blank magazine capacity: 300-400 pcs

- Open cardboard dimensions: min 300x500 mm max 750x1300 mm – min 11.81"x19.69" mm max 29.53"x51.18" mm

- Cardboard thickness: from 1,8 mm up to 3 mm or from 0,54 mm up to 0,60 mm (kraft)

- Automatic pack collation

- In line infeed conveyor with adjustable speed controlled by Inverter

- One-row or multi-row infeed

- Product presence photocells

- Accumulation/control rows photocells

- Cardboards pick-up by means of an oscillating arm with suction cups, driven by servomotor

- Automatic positioning of the cardboards pick-up and release point, driven by gearmotor and controlled by encoder and inverter

- Cardboard positioning on the polizene guides, without contact with the transmission chains

- Electronic forming unit driven by 4 servomotors, with automatic adjustment of the carton depth

- Pneumatic side vanes to guide the cardboard flaps

- Load of the product into the open U-shaped carton with double 2 cartesian axis motorized pusher controlled by 4 servomotors

- Gate with pneumatic movement with opening function and guide of the prooducts

- Closure of the inside lateral flaps by pneumatic actuators

- Folding of the upper part of the cardboard by means of fixed contrast

- Motorized transversal Hot melt glue applicator, controlled by inverter and encoder

- 4 longitudinal fixed gluing points

- Closure of the external flaps and squaring of the finished case by pneumatic actuators

- Flxmod® control system equipped with:

- operator Interface 7" full-colour touch screen sliding all along the length of the machine

- Plc

- inverter with integrated encoder reading

- IN/OUT control modules

- 50 different memorisable working cycles

- 4.0 industry compliant

- Designed and manufactured according to CE regulations

Contact us

- SMIPACK S.p.A.

- Address: Via Piazzalunga, 30

24015 San Giovanni Bianco BG

Italy - Phone: +39 0345 40.400

- E-mail: info.smipack@smigroup.net

- Monday - Friday: 08:00 - 12:00 / 13:30 - 17:30

Saturday - Sunday: Closed

Privacy statement

TRANSPARENCY

![]()

Lawfulness of processing

All activities relating to personal data processing shall be lawful (consent, contract obligations, vital interests of the data subject or of third parties, compliance with legal obligations to which the controller is subject, public interest or exercise of official authority, legitimate interest pursued by the controller or by third parties).

![]()

Information statement

The information statement has been improved and updated to the new regulations (art. 13 and 14 GDPR).

![]()

Rights of the data subjects (right of access, right to erasure-right to be forgotten, right to restriction of processing, right to object, right to data portability)

Technical and organization measures have been adopted to ensure the data subject's exercise of his rights and to meet the data subject requirements.

![]()

Controllers, processors

Based on the new principle of “accountability”, SMI Group organization was re-defined, in order to proactively ensure integral compliance with the Regulation.

Redefinition of the role of data processors and service suppliers whose activity implies personal data processing.

![]()

Risk of data processing; accountability measures taken by controllers and processors (Impact assessment, record of processing activities, security of processing, data breach)

The “Conformity document”, including records of data processing activity, plans, adopts and demonstrates all technical and organizational measures taken to adequately perform the data processing activities and specifies the necessary procedures to be adopted to notify data breach.

![]()

Transfer of personal data to international organizations

Smipack adheres to the general principles and guarantees concerning the transfer of personal data to third Countries.

The Controller is:

SMIPACK S.p.A.

Head office: Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) ITALY

VAT nr: IT02529010163 - R.E.A. 234981

For further information, write to: privacy@smigroup.net

According to the European Regulation 679/2016, the data subject is entitled to exercise the rights set forth in the Regulation.

The integral version of art. 15; 16; 17; 18; 20; 21; 77 of the European Regulation is attached to this document.

In order to exercise your rights, please send the application form duly filled in to the Controller's address.

Legal notice

SMIPACK S.p.A.

Società sottoposta a direzione e coordinamento da SMIGROUP S.p.A.

Società appartenente al GRUPPO IVA SMI INDUSTRIES

Sede amministrativa:

Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

Tel. +39 0345 40.400 - Fax: +39 0345 40.409 - www.smipack.it

C.F. 02529010163 - P. IVA IT04471940165 - R.E.A. 302062

Iscr.Reg.Imprese 02529010163 - Cap. Soc. € 1.000.000 i.v.

Sede legale:

Via Monte Grappa, 7 - 24121 Bergamo (BG) - ITALIA

Unità produttiva:

Via Piazzalunga, 30 - 24015 San Giovanni Bianco (BG) - ITALIA

Tel. +39 0345 40.400 - Fax: +39 0345 40.419

Ufficio vendite:

Via Piazzalunga, 30 - 24015 San Giovanni Bianco (BG) - ITALIA

Tel. +39 0345 40.400 - Fax: +39 0345.40.409