- Who we are

- Governance

- Products

- PACKAGING TECHNOLOGY OPEN TO EVERYONE

- L-seal hood packersSL Series

- L-seal hood packersS Series

- L-sealer, automatic L-sealer, shrinking tunnelFP Series

- Continuous automatic sealers with shrink tunnelHS Series

- Automatic flow pack machinesFW Series

- Semi-automatic and automatic shrink wrappers with sealing barBP Series

- Automatic overlap shrink wrappersXP Series

- Wrap-around case packersWPS Series

- Automatic handle applicatorsHA Series

- Services

- Media center

- News

- Contacts

- Careers

- Who we are

- Governance

- Products

- PACKAGING TECHNOLOGY OPEN TO EVERYONE

- L-seal hood packersSL Series

- L-seal hood packersS Series

- L-sealer, automatic L-sealer, shrinking tunnelFP Series

- Continuous automatic sealers with shrink tunnelHS Series

- Automatic flow pack machinesFW Series

- Semi-automatic and automatic shrink wrappers with sealing barBP Series

- Automatic overlap shrink wrappersXP Series

- Wrap-around case packersWPS Series

- Automatic handle applicatorsHA Series

- PACKAGING TECHNOLOGY OPEN TO EVERYONE

- Services

- Media center

- News

- Contacts

- Careers

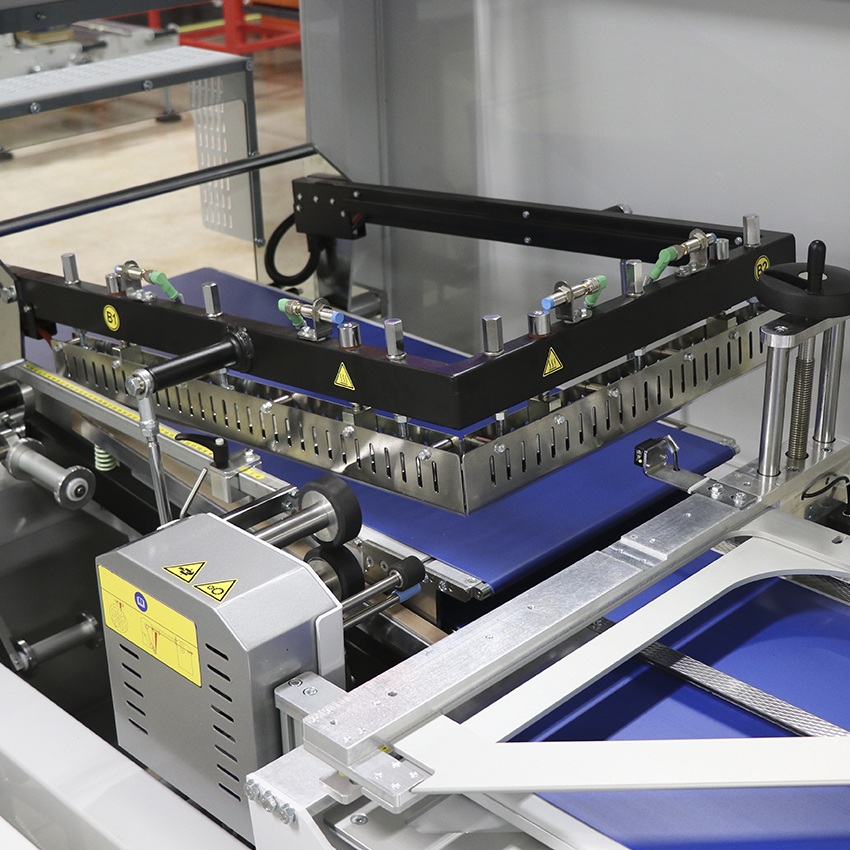

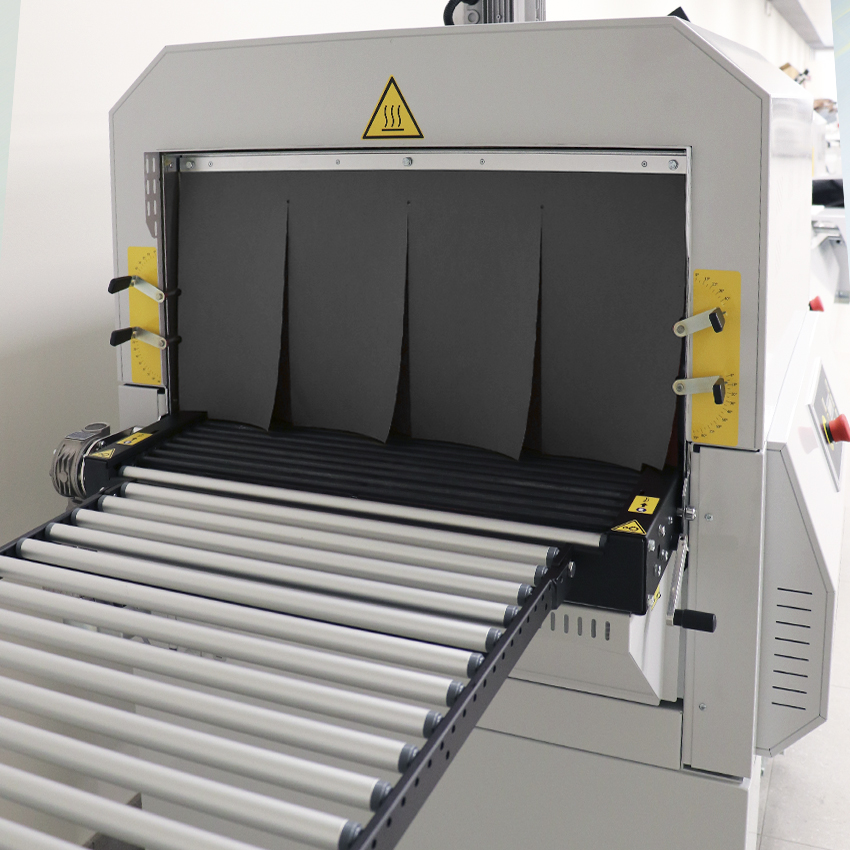

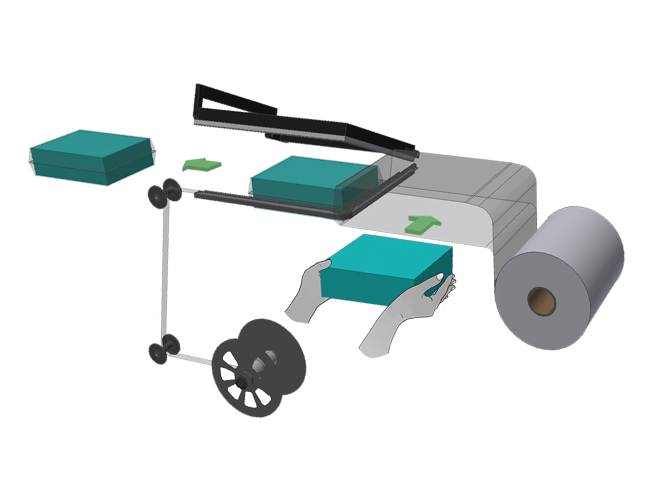

Semi-automatic and automatic L-sealers with shrink tunnel

FP Series

FP560A - Semi-automatic L-sealer

The semi-automatic and automatic “Full Electric” packers with L-sealing system from the FP series are characterized by great quality/price ratio and modularity. All models of this range can indeed be supplied with or without shrink tunnel.

The INOX version of these machines is ideal for meeting the needs of the food industry; it features a stainless steel frame (AISI 304) and is equipped with a conveyor belt in compliance with FDA, UE and USDA regulations for contact with food.

Compared to the traditional L-sealers, the FP series provides higher outputs as well as the possibility of using Polyethylene film, besides the traditional shrink films, and includes different models for outputs ranging up to 3600 packs/hour.

MARKET SECTORS

Bakery, confectionery, dairy products, fruit & vegetables, fish, meat, eggs, printing industry, stationery, computer industry, laundry, household products, toys, cosmetics, pharmaceutical, electric-electronic, plastic, wood, paper, detergents, mechanical industry, lubricants, cases & boxes, shelving, logistic, co-packers.

| Power supply | 220 - 240 V |

| 1PH + N + PE | |

| 50/60 Hz | |

| Installed power | 2500 W |

| Sealing bar | 560 x 430 mm |

| Maximum pack height | 230 mm |

| Speed of conveyors | 19 m/min |

| Output up to | 1500 pph ** |

| Maximum size of film reel | 600 - ø 300 mm |

| Machine size | 2010 x 790 mm |

| h 1050 mm | |

| Machine net weight | 148 Kg |

| Usable Films: Pvc, Polyolefins and Polyethylene | up to 50 µ |

(**) Packs per hour. The stated speed can change according to the product size, the pack collation and the type of film used.

- Continuous cycle sealing

- Pack deviation device

- Film waste winding device as standard supply

- PTFE-coated sealing blade

- Closed-circuit liquid cooling of the sealing bars

- Viewer of the coolant level

- Working height of the sealer and of the tunnel adjustable by means of an external crank

- Mobile product-holding plate, loose from the film reel support to allow a better adjustment of the film to the pack size

- Emergency button

- Automatic pack discharge by means of a motorized conveyor

- Flextron® control system equipped with:

- Alphanumeric LCD control panel provided with a 16-bit microprocessor card and solid state relays

- Modular power section, separated from the control panel and characterized by:

- longer-lasting solid state relays providing easier maintenance

- in case of failure, possibility of replacing just the damaged module, without losing the data stored in the memory

- This system allows a simple and precise control of all the machine operations, such as:

- machine status

- number of packs produced by an electronic pack counter

- real-time production

- adjustment of the sealing temperature

- pack discharge speed

- automatic hood closing and re-opening, motorized and managed by inverter

- delay in the opening of the sealing arm

- sealing arm safety device

- possibility of scheduling up to 10 different work cycles, thus resulting in increased productivity and simplified use

- troubleshooting

- Reduced power consumption

- Compliance with CE regulations

Contact us

- SMIPACK S.p.A.

- Address: Via Piazzalunga, 30

24015 San Giovanni Bianco BG

Italy - Phone: +39 0345 40.400

- E-mail: info.smipack@smigroup.net

- Monday - Friday: 08:00 - 12:00 / 13:30 - 17:30

Saturday - Sunday: Closed

Privacy statement

TRANSPARENCY

![]()

Lawfulness of processing

All activities relating to personal data processing shall be lawful (consent, contract obligations, vital interests of the data subject or of third parties, compliance with legal obligations to which the controller is subject, public interest or exercise of official authority, legitimate interest pursued by the controller or by third parties).

![]()

Information statement

The information statement has been improved and updated to the new regulations (art. 13 and 14 GDPR).

![]()

Rights of the data subjects (right of access, right to erasure-right to be forgotten, right to restriction of processing, right to object, right to data portability)

Technical and organization measures have been adopted to ensure the data subject's exercise of his rights and to meet the data subject requirements.

![]()

Controllers, processors

Based on the new principle of “accountability”, SMI Group organization was re-defined, in order to proactively ensure integral compliance with the Regulation.

Redefinition of the role of data processors and service suppliers whose activity implies personal data processing.

![]()

Risk of data processing; accountability measures taken by controllers and processors (Impact assessment, record of processing activities, security of processing, data breach)

The “Conformity document”, including records of data processing activity, plans, adopts and demonstrates all technical and organizational measures taken to adequately perform the data processing activities and specifies the necessary procedures to be adopted to notify data breach.

![]()

Transfer of personal data to international organizations

Smipack adheres to the general principles and guarantees concerning the transfer of personal data to third Countries.

The Controller is:

SMIPACK S.p.A.

Head office: Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) ITALY

VAT nr: IT02529010163 - R.E.A. 234981

For further information, write to: privacy@smigroup.net

According to the European Regulation 679/2016, the data subject is entitled to exercise the rights set forth in the Regulation.

The integral version of art. 15; 16; 17; 18; 20; 21; 77 of the European Regulation is attached to this document.

In order to exercise your rights, please send the application form duly filled in to the Controller's address.

Legal notice

SMIPACK S.p.A.

IVA SMI INDUSTRIES Group

Headquarters: Via Carlo Ceresa, 10

24015 San Giovanni Bianco (BG) ITALY

Registered office: Via Monte Grappa, 7 - 24121 Bergamo (BG) - ITALY

VAT: 04471940165 - TAX code: 02529010163 - R.E.A.: 234981

Share capital: Euro 5.000.000 i.v.